Gear Shield® NC

When it comes to best girth gear grease Petron is the world leader in lubricants for open gear drives on stationary rotating machinery. Gear Shield® is a high-viscosity lubricant for open gears that provides superior separation of gear teeth in the heaviest loaded zone of gear tooth mesh. Rich in high-viscosity base fluid combined with E.P. and oxidation-resistant additives further enhancing this protection capability. Readily pump able for good lubrication distribution and easily drainable. Petron Gear Shield® is a choice for: mills and kilns in mineral processing, power generation, windmills, steel, and cement industries.

Petron Gear Shield Lubricants for Open Gears offers the following benefits:

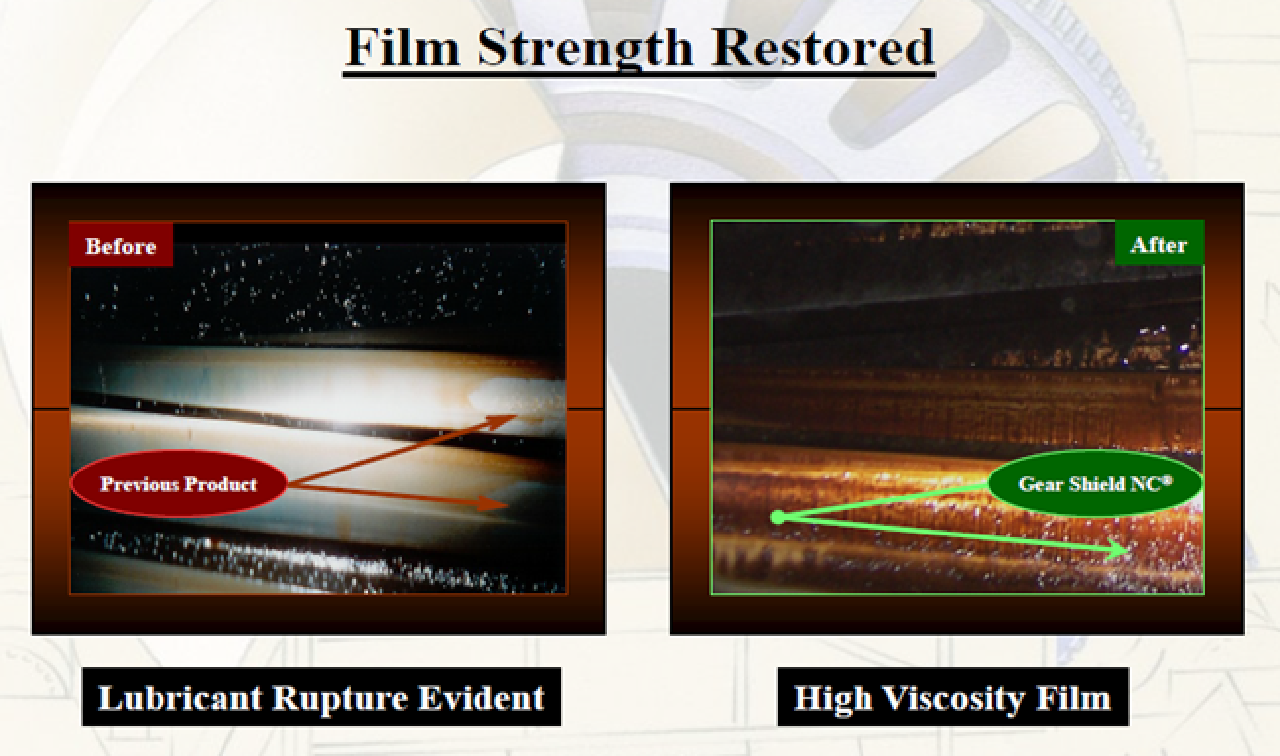

Restores high viscosity grease film strength on pinion and girth gear.

Eliminates lubricant film rupture.

Exceeds the OEM recommended Lube Film minimum Thickness requirements.

Reduced wear longer life of gears, so lesser maintenance.

Best Lubricants for Open Gears Types Offered by Petron Corp. USA

These are highly viscus best Lubricants for Open gears that provide better thickness between gear teeth exceeding AGMA requirements which results in reduced lubricant consumption and cost including waste management for open gear and disposal.

GEAR SHIELD® NC – Lubricants for Open Gears

Petron Gear Shield® NC is the world leader in lubricants for open gears drives on stationary rotating machinery. Gear Shield® NC is a high-viscosity gear grease that provides superior separation of gear teeth in the heaviest loaded zone of gear tooth mesh. Gear Shield® NC is a high-viscosity based best girth gear lube combined with E.P. and oxidation-resistant additives further enhancing this protection. The product is formulated to be readily pumpable for good lubrication distribution and easily drainable. The High Viscosity base fluid allows for economically controlled application of lubricant using a Automatic Lubrication Spray system. Petron Gear Shield® NC is the open gear lube of choice for mills and kilns in Mineral processing, Power generation, Steel, and Cement industries.

- High Viscosity lubricants for open gears designed to lubricate heavily loaded gears.

- Highest EDH values of any open gear market.

- Anti-wear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones of gear tooth mesh.

- Industry-leading FZG wear test result.

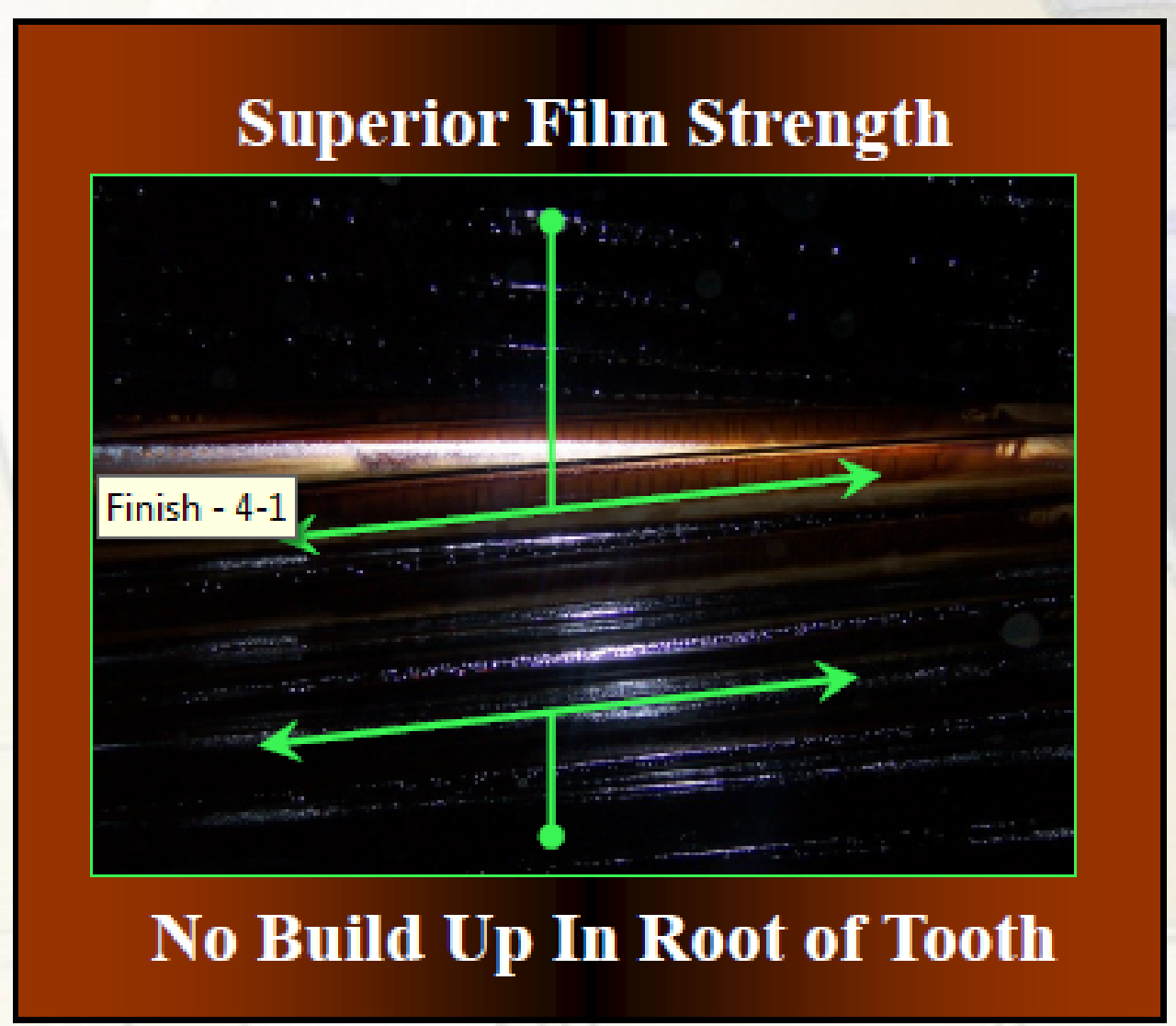

- No build-up in gear tooth roots.

- Drains freely from gear guards and drains freely from gear guards.

- Optimum Consumption as per AGMA & OEM guidelines.

- Pumps freely down to 32°F (0°C). For applications below 32°F (0°C) use Gear Shield NCW.

- Environmentally friendly. Does not contain chlorinated solvents or lead and is free of all carcinogens.

- Environmentally Safe/Passes TCLP Protocol A.

Petron Gear Shield® NC is best grease for metal gears which can be used in Ball Mills, Sag Mills, Rod Mills, Balling Discs, Kilns, Dryers, Quenchers, and Mixers.

Petron Gear Shield® NC is open gear grease spray that can be applied by spraying, brushing or dripping.

Petron Gear Shield® NC is designed to be sprayed through all automatic lubrication equipment.

Petron Gear Shield® NC is available in spray cans, pails, kegs, drums, bin tanks, and tank trucks.

Notes:

Petron Gear Shield® NC exceeds OEM and AGMA base oil viscosity requirements for open gear lubricants applied by intermittent spray application.

Pumps freely down to 32 def. F (0 deg. C). For colder applications, i.e. ambient temperature below 0 deg. C use Gear Shield® NCW, below.

No. | Property | Test Method | Typical Data |

1. | Color | Visual | Black |

2. | Appearance | Visual | Viscous |

3. | Base Oil Viscosity, cSt @ 40 Deg. | ASTM | >55,000 |

4. | Undiltued Viscosity, cSt @100 | ASTM | >1,600 |

5. | Finished Viscosity, cSt @ 40 Deg. | ASTM | 6,000 |

6. | Specific Gravity | ASTM | 0.96 |

7. | Flash Point | ASTM | >250 |

8. | 4 Ball, Wel, Kg | ASTM | 400 |

9. | Load Wear Index | ASTM | 77 |

10. | 4 Ball Wear (scar diam., mm) | ASTM | 0.49 |

11. | FZG Load Stages Passed | DIN | >12 |

12. | FZG Specific Mass Loss (mg/kW.h) | DIN | 0.05 |

13. | FZG 30 hr Mass Loss (mg) L.S. 10 | DIN | 20 |

14. | Film Life Test (minutes) @ L.S. 7 | DIN | 33 |

15. | Mobility@ 32 Deg. F, g/s | US | 0.03 |

16. | Ventometer, 600 psi | Linbcoln | 32 |

17. | Rust Prevention | ASTM | Pass |

| · Emissivity data setting for hand held temperature devices to be ser at 0.90 · Testing listed is typical, no warranty is expressed or implied regarding results obtained from use. Information contained on this Product Data Sheet is subject to change without | ||

Click to download Product Data Sheet GEAR SHIELD® NC

Pumps freely down to 0 def. F (-18 deg. C). For applications ambient temperature above 32® deg. C use Gear Shield® NC, above.

| |||

No. | Property | Test Method | Typical Data |

1. | Color | Visual | Black |

2. | Appearance | Visual | Viscous |

3. | Base Oil Viscosity, cSt @ 40 Deg. | ASTM | >55,000 |

4. | Finished Viscosity, cSt @ 40 Deg. | ASTM | 1,600 |

5. | Specific Gravity | ASTM | 0.96 |

6. | Flash Point | ASTM | >200 |

7. | 4 Ball, Weld, Kg | ASTM | 400 |

8. | Load Wear Index | ASTM | 77 |

9. | 4 Ball Wear (scar diam., mm) | ASTM | 0.49 |

10. | FZG Load Stages Passed | DIN | >12 |

11. | FZG Specific Mass Loss (mg/kW.h) | DIN | 0.05 |

12. | FZG 30 hr Mass Loss (mg) @ L.S. | DIN | 20 |

13. | Mobility@ 32 Deg. F, g/s | US | 0.02 |

14. | Ventometer, 600 psi | Linbcoln | 0 |

15. | Rust Prevention | ASTM | Pass |

· Emissivity data setting for · Testing listed is typical, no · Before using always be sure to | |||

Click to download Product Data Sheet Open Gear Lubricant GEAR SHIELD® NCW

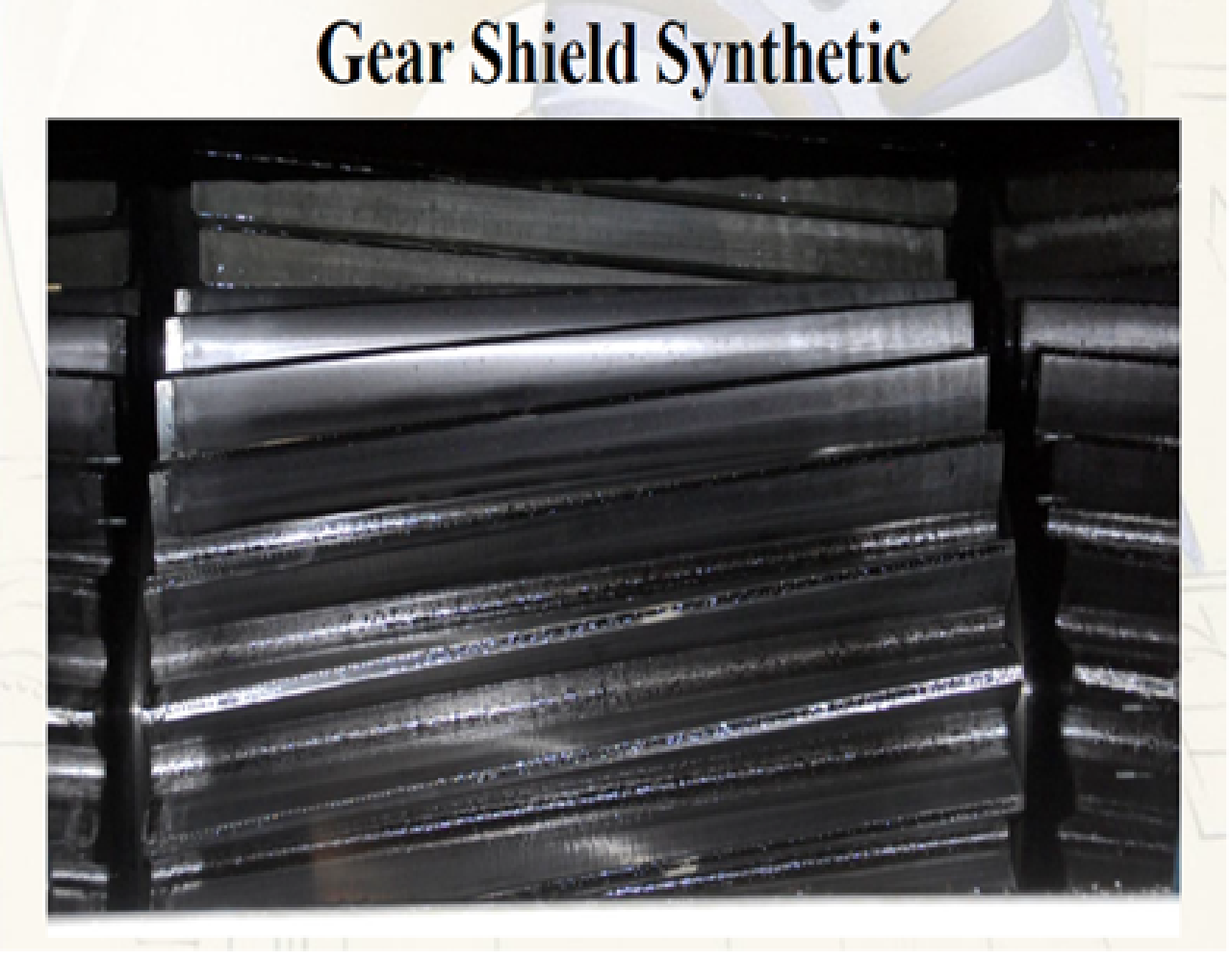

Pumps freely down to 0 deg. F ( -18 deg. C). For colder applications, heating may be required.

| |||

No. | Property | Test Method | Typical Data |

1. | Color | Visual | Amber |

2. | Apperance | Visual | Viscous |

3. | Base Oil Viscosity, cSt @ 40 Deg. | ASTM | >40,000 |

4. | Undiltued Viscosity, cSt @100 | ASTM | >1,600 |

5. | Finished Viscosity, cSt @ 40 Deg. | ASTM | 7,200 |

6. | Flash Point | ASTM | 385 |

7. | Pour Point | ASTM | 10 |

8. | 4 Ball, Weld, Kg | ASTM | 800 |

9. | FZG Load Stages Passed | DIN | >12 |

10. | FZG Specific Mass Loss (mg/kW.h) | DIN | 0.02 |

11. | Ventometer, 600 psi | Linbcoln | 0 |

12. | Rust Prevention | ASTM | Pass |

• Emissivity data setting for hand • Testing listed is typical, no warranty • Before using always be sure to read | |||

Click to download Product Data Sheet for Open Gear Lubricant GEAR SHIELD® Synthetic

Pumps freely down to 15 deg. F (-9 deg. C).

| |||

No. | Property | Test Method | Typical Data |

1. | Color | Visual | Balck |

2. | Apperance | Visual | Viscous, Semi Fluid |

3. | Specific Gravity | ASTM D-1298 | 0.92 |

4. | Cooper Corrosion | ASTMD-130 | 1B |

5. | Flash Point | C.O.C. | 245 Deg. F (>118 Deg. C) |

6. | 4 Ball, Weld, Kg | ASTM D-2596 | 400 |

7. | Load Wear Index | ASTM D-2596 | 70 |

8. | 4 Ball Wear (scar diam., mm) | ASTM D-2266 | 0.6 |

9. | Timken OKJ Load, Lbs | ASTM D-2509 | 45 |

10. | Ventmeter @ 30 Deg. F | Lincoln VE-1 | 30 secords <300 psi |

11. | Viscosity, cSt @ 100 Deg. C (Undiluted) | ASTM D-445 | 1150 to 1350 |

12. | Viscosity, cSt @ 40 Deg. C (Diluted) | ASTM D-445 | 4800 to 6800 |

• Emissitivity data setting for hand held temperatrue devices to be set at 0.90 • Testing listed is typical, no warranty is expressed or implied regarding results obtained from use. Information contained on this Product Data Sheet is subject to change without notification. Seller shall not be liable for any loss or damage. • Before using always be sure to read and follow precautions, and directions for use appearing on the product container. | |||

Click to download Product Data Sheet for Open Gear Lubricant GEAR SHIELD® P

High viscosity synthetic lubricant designed for use at both and elevated temperatures.

No. | Property | Test Method | Typical Data | |

|

|

| KL 200 | KL 300 |

1. | Viscosity | ASTM | ASTM | ASTM |

2. | cSt @ 40 Deg. C |

| 6,975 | 10,619 |

3. | cSt @ 100 Deg. C |

| 236 | 359 |

4. | Viscosity Index | Calculated | 136 | 157 |

5. | Flash Point | ASTM | 401 | 401 |

6. | Pour Point | ASTM | 21 | 43 |

7. | Cooper Corrosion | ASTM | 1B | 1B |

8. | Load Wear Index | ASTM | 59.26 | 59.26 |

9. | Last Non-Seizure Load (kg) / Scar | ASTM | 126/0.45 | 126/0.45 |

10. | Last Seizure Load (kg) / Scar | ASTM | 200/1.28 | 200/1.28 |

11. | Weld Load (kg) | ASTM | 250 | 250 |

12. | Four Ball Wear with Coefficient | ASTM | 0.085 | 0.085 |

13. | Density, Specific Gravity @ 60 | ASTM | 0.9059 | 0.9065 |

14. | Punds /Gallon @ 60 deg. F | ASTM | 7.544 | 7.548 |

• Emissivity data setting for hand • Testing listed is typical, no warranty • Before using always be sure to read | ||||

Click to download Product Data Sheet Open Gear Kiln Lube GEAR SHIELD® Open Gear Lubricant

Proof Of Performance - Lubricants For Open Gears

Please visit page Proof of Performance for Cement Industry for details. Below the is the summary for ready reference.

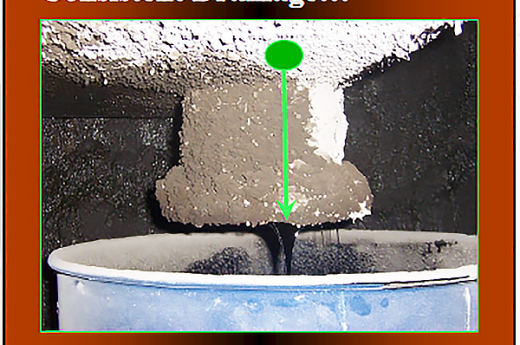

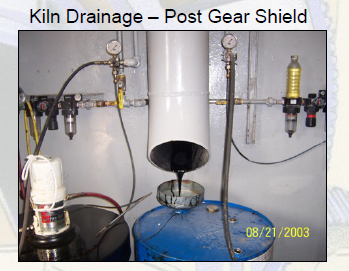

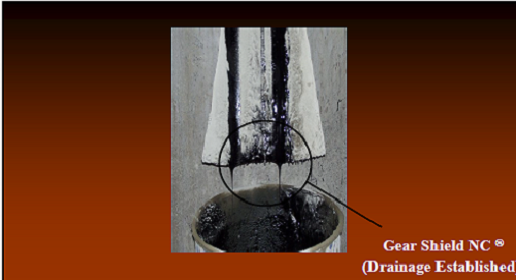

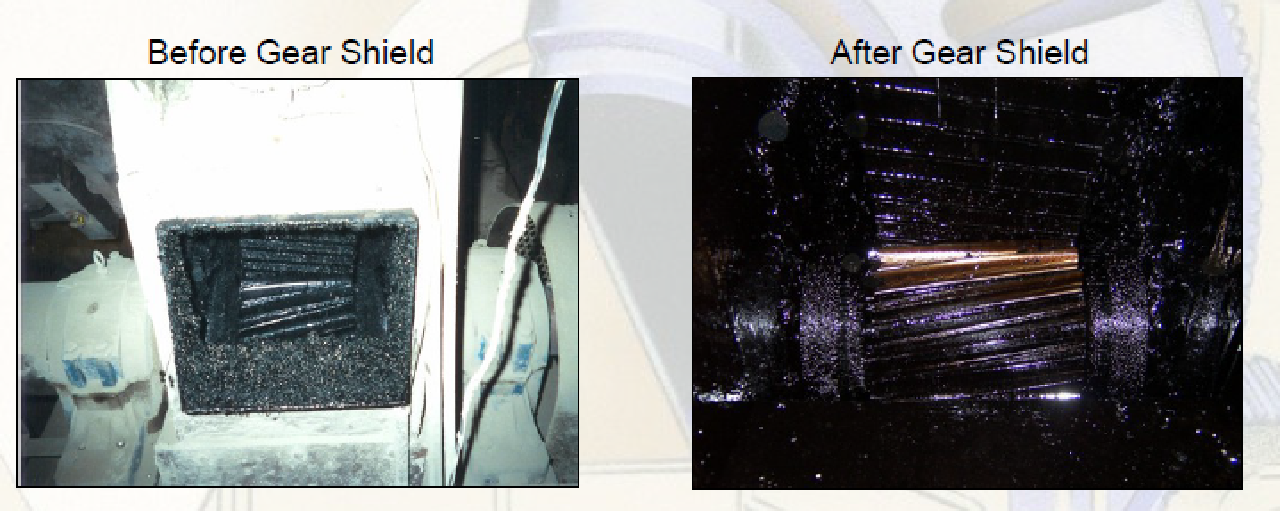

A. Consistent Drainage Established – Elimination of Lubricant build-up on Gears / Guards

Lubricant build-up eliminated through Gear Shield superior drainage capability.

Drainage problem solved.

Consistent drainage eliminates Lubricant Bulid-up inside gear guard.

Elimination of lubricant build-up on gears.

Consistent drainage of Petron Gear Lube flushes air borne contaminants from girth gear.

Elimination of housekeeping issues. Improved housekeeping.

Elimination of lubricant build-up.

Before

After

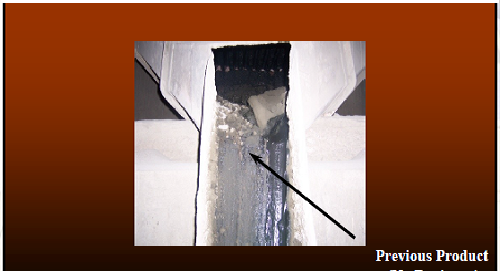

B. No build-up in Root of Gears Tooth - Lubricants for open gears

Lubricant build-up eliminated through Gear Shield superior drainage capability.

Risk of exposure of gear to air borne contaminates mitigated.

Superior Film strength on gear tooth.

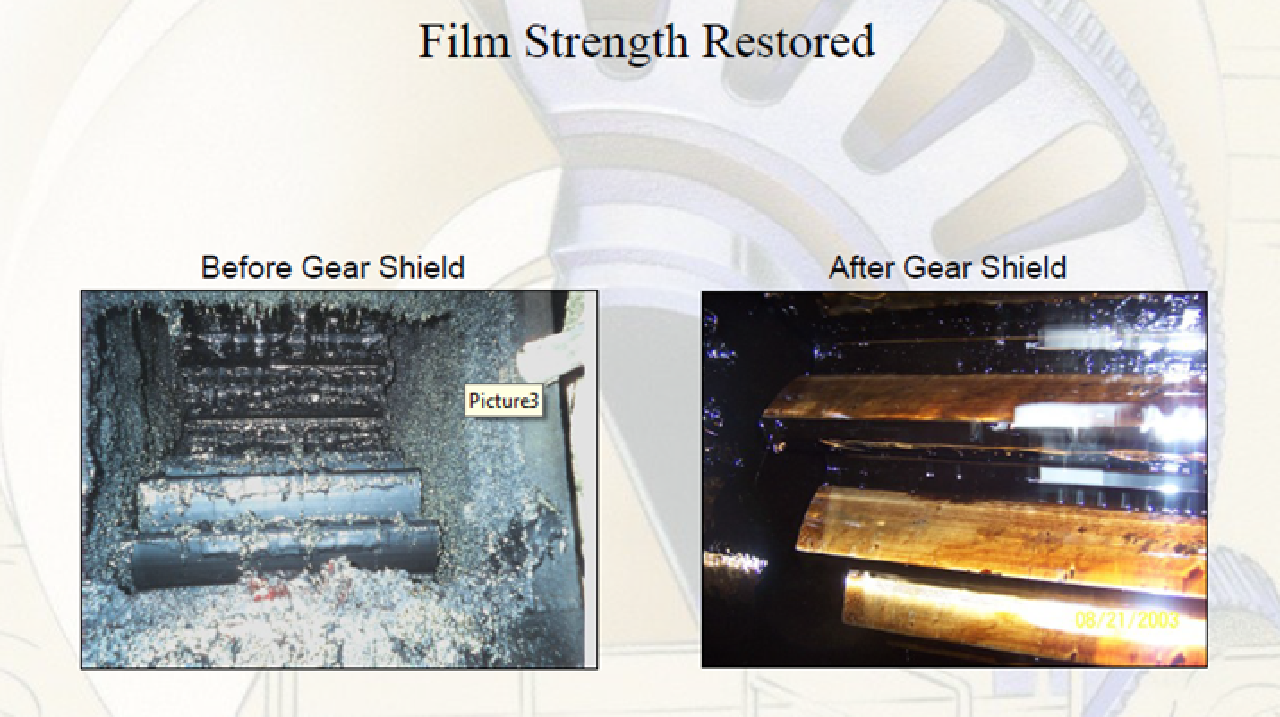

C. Elimination of Lube Film Rupture - Restoration of Lubricant Film Strength

Lubricant film rupture eliminated.

High viscosity Lubricant Film strength restored on pinion and girth gear.

The Gear Shield exceeded the OEM recommended Lube Film minimum Thickness requirements.

Lubricant Lambda (lubricant film thickness) exceeds AGMA recommended standard of four (4) or greater.

For above listed gear grease types and their proof of performance to find why Petron Gear Shield is the best grease for metal gears due to lower consumption hence reduced lubricant cost & inventory, easy (without buildup & clogging) drainage establishment and others benefits.

Please contact us regarding open gear grease provided by Petron Lubricant Center in UAE and some other countries.