Lubricant for Gyratory Crusher Shaft and Sleeve

Performance Products Tech (FZE) has introduced high-performance engineered (specialty) spider bushing lubricant Gyratory, which provides protection under all operating conditions.

The Petron gyratory crusher shaft and sleeve lubricant is a high-viscosity fluid designed to flow allowing the lubricant to coat the entire shaft and bushing, extending component life while reducing consumption and cost. Please refer below for more details regarding benefits.

Performance Products Tech (FZE) Lubricant for gyratory crusher shaft and the sleeve is a non-polymer, viscous, semi-fluid, lubricant designed to lubricate spider bushings found in crusher applications. The Engineered Lubricant provides maximum protection to gyratory crusher bushings in all conditions. Petron lubricant for Crusher Spider Bushing lubrication provides superior, proven cold-temperature pumpability, coupled with nanotechnology to assure maximum protection of crusher spider bushings, and is designed to be applied through all automatic lubrication equipment.

Features & Benefits

Formulated to lubricate heavily loaded crusher spider bushings.

High viscosity fluid designed to flow allowing the lubricant to coat the entire shaft and bushing, extending component life while reducing consumption.

Solid and organo-metallic anti-wear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones.

Recommended for use in all ambient temperature conditions, both summer and winter.

It does not use polymers to attain its high viscosity.

Environmentally friendly, does not contain chlorinated solvents or lead and is free of all known carcinogens.

Petron Crusher Spider Bushing Lubricant is recommended in colder climates.

Petron Crusher Spider Bushing H Lube is recommended in warmer climates.

Gyratory crusher shaft and sleeve lubricant Application

Petron Crusher Spider Bushing Lubricant is designed to lubricate spider bushings found in crusher applications. Petron Lubricant for Crusher Spider Bushing is designed to be applied through all automatic lubrication equipment.

Petron Crusher Spider Bushing Lubricant is available in two grades. Both are packaged in pails, kegs, drums, bin tanks, and one-way bulk flexible bag.

Petron lubricant for Crusher Spider bushing & shaft is a non-polymer, viscous, semi-fluid, lubricant designed to lubricate spider bushings found in crusher applications. Crusher Spider Bushing Lubricant provides maximum protection to gyratory crusher spider bushings in all conditions. Crusher Spider Bushing Lubricant provides superior, proven cold-temperature pumpability, coupled with nanotechnology to assure maximum protection of crusher spider bushings, and is designed to be applied through all automatic lubrication equipment.

Features & Benefits

Formulated to lubricate heavily loaded crusher spider bushings.

High viscosity fluid designed to flow allowing the lubricant to coat the entire shaft and bushing, extending component life while reducing consumption.

Solid and organo-metallic anti-wear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones.

Recommended for use in all ambient temperature conditions, both summer and winter.

It does not use polymers to attain its high viscosity.

Environmentally friendly, does not contain chlorinated solvents or lead and is free of all known carcinogens.

Petron Crusher Spider Bushing Lubricant is recommended in colder climates.

Petron Crusher Spider Bushing H Lube is recommended in warmer climates.

Product Application

Petron Crusher Spider Bushing Lubricant is designed to lubricate spider bushings found in crusher applications. Petron Lubricant for Crusher Spider Bushing is designed to be applied through all automatic lubrication equipment.

Petron Crusher Spider Bushing Lubricant is available in two grades. Both are packaged in pails, kegs, drums, bin tanks, and one-way bulk flexible bag.

Petron Crusher Spider Bushing Lubricant is a non-polymer, viscous, semi-fluid, lubricant designed to lubricate spider bushings found in crusher applications. Crusher Spider Bushing Lubricant provides maximum protection to gyratory crusher spider bushings in all conditions. Crusher Spider Bushing Lubricant provides superior, proven cold-temperature pumpability, coupled with nanotechnology to assure maximum protection of crusher spider bushings, and is designed to be applied through all automatic lubrication equipment.

Features & Benefits of Petron Engineered Lubricant for Gyratory Crushers – Best lubricant for bushings

Formulated to lubricate heavily loaded crusher spider bushings.

High viscosity fluid designed to flow allowing the lubricant to coat the entire shaft and bushing, extending component life while reducing consumption.

Solid and organo-metallic anti-wear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones.

Recommended for use in all ambient temperature conditions, both summer and winter.

It does not use polymers to attain its high viscosity.

Environmentally friendly, does not contain chlorinated solvents or lead and is free of all known carcinogens.

Petron Crusher Spider Bushing Lubricant is recommended in colder climates.

Petron Crusher Spider Bushing H Lube is recommended in warmer climates.

Product Application – Shaft Lubrication

Petron Crusher Spider Bushing Lubricant is designed to lubricate spider bushings found in crusher applications. Petron Lubricant for Crusher Spider Bushing is designed to be applied through all automatic lubrication equipment.

Petron Crusher Spider Bushing Lubricant is available in two grades. Both are packaged in pails, kegs, drums, bin tanks, and one-way bulk flexible bag.

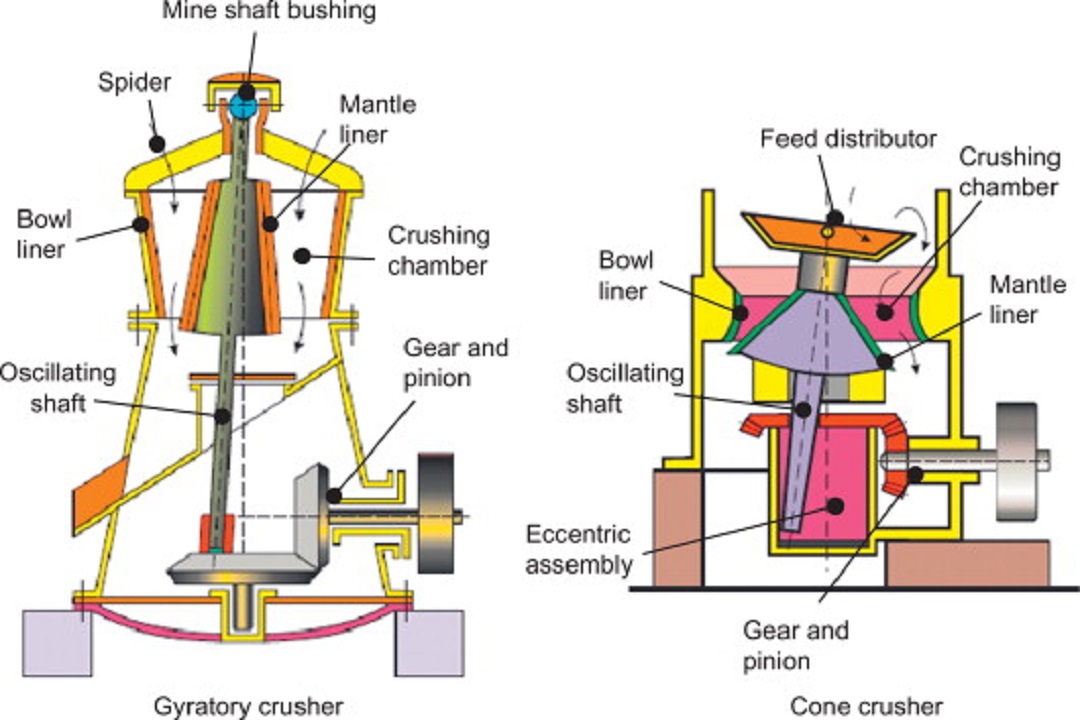

The Gyratory crushers basically work on a similar principle to that of jaw-type crushers but Gyratory Crusher has a circular gap at bottom from where the crushed material discharges.

The gyratory type of crusher has a solid cone mounted on a revolving shaft and housed within a hollow body, which has vertical or conical sloping sides. Rock material is compressed between a static bowl and concave mantle which oscillates about the central axis, the rock is crushed and broken when the crushing surfaces approach each other, the crushed rocks fall through the discharge hole.

The gyratory type of crusher is normally designed for primary crushing in large-scale rock crushing applications up to 6000 t/h.

Gyratory crushers are for primary crushing, normally used for crushing minerals as mined. The purpose of Jaw crushers is to reduce rocks to smaller sizes for the next crushing stages.

Product Description - Specialty lubricants for Crushers

Petron Bushing Lubricant is a non-polymer, viscous, semi-fluid, lubricant designed to lubricate spider bushings found in crusher applications. Crusher Spider Bushing Lubricant provides maximum protection to gyratory crusher spider bushings in all conditions. Crusher Spider Bushing Lubricant provides superior, proven cold-temperature pumpability, coupled with nanotechnology to assure maximum protection of crusher spider bushings, and is designed to be applied through all automatic lubrication equipment.

Features & Benefits – Specialty Lubricants for Crushers

Formulated to lubricate heavily loaded crusher spider bushings.

High viscosity fluid designed to flow allowing the lubricant to coat the entire shaft and bushing, extending component life while reducing consumption.

Solid and organo-metallic anti-wear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones.

Recommended for use in all ambient temperature conditions, both summer and winter.

It does not use polymers to attain its high viscosity.

Environmentally friendly, does not contain chlorinated solvents or lead, and is free of all known carcinogens.

Petron Crusher Spider Bushing Lubricant is recommended in colder climates.

Petron High-Performance Crusher Spider Sleeve H Lube is recommended in warmer climates.

Product Application –

The specialty spider bushing & shaft Lubricant is designed to lubricate spider bushings found in crusher applications. Petron Lubricant for Crusher Spider Bushing is designed to be applied through all automatic lubrication equipment.

The Petron LUBRICANT FOR SPIDER BUSHINGS OF GYRATORY is a non-polymer, viscous, semi-fluid, lubricant designed to lubricate spider bushings found in crusher applications.

Petron Gyratory Crusher sleeve Lubricant is available in two grades. Both are packaged in pails, kegs, drums, bin tanks, and one-way bulk flexible bag.

| No. | Property | Test Method | Typical Data | |

|---|---|---|---|---|

| Crusher Spider Bushing | Crusher Spider Bushing H | |||

| 1 | Color | Visual | Brownish Black | Brownish Black |

| 2 | Appearance | Visual | Viscous, Semi-Fluid | Viscous, Semi-Fluid |

| 3 | Flash Point | ASTM- D-92 (C.O.C) | 160 Deg. C | 160 Deg. C |

| 4 | 4 Ball EP, Weld Point (Kg) | ASTM D-2596 | 315 | 315 |

| 5 | Ventmeter, 600 psi, 30 seconds | Lincoln VE-1 | -20 Deg. C | 0 Deg. C |

| 6 | VViscosity, cPs @ 72 Deg. F | PTM 114 | 15,000 | 95,000 |

| In extremely cold weather it is important that you are able to slowdown the actuation of the pump and extend out the fault timers in order successful as you approach extreme cold conditions. You must also make sure vent meter reading in seconds as posted on PDS are acceptable for injector model and machinery you plan to lubricate. The published vent time, when added to the required time to reach system pressure must be less than the cycle time set on the PLC of the auto lube system. Injector blocks should be as close as possible to site application. | ||||

The Values listed for gyratory crusher shaft and sleeve lubricant are typical, normal manufacturing variations are expected. The information contained in the Product Data Sheet is subject to change without notification. Before using this product always be sure to read and follow precautions and directions for use appearing on product container. Seller shall not be liable for any loss or damage.

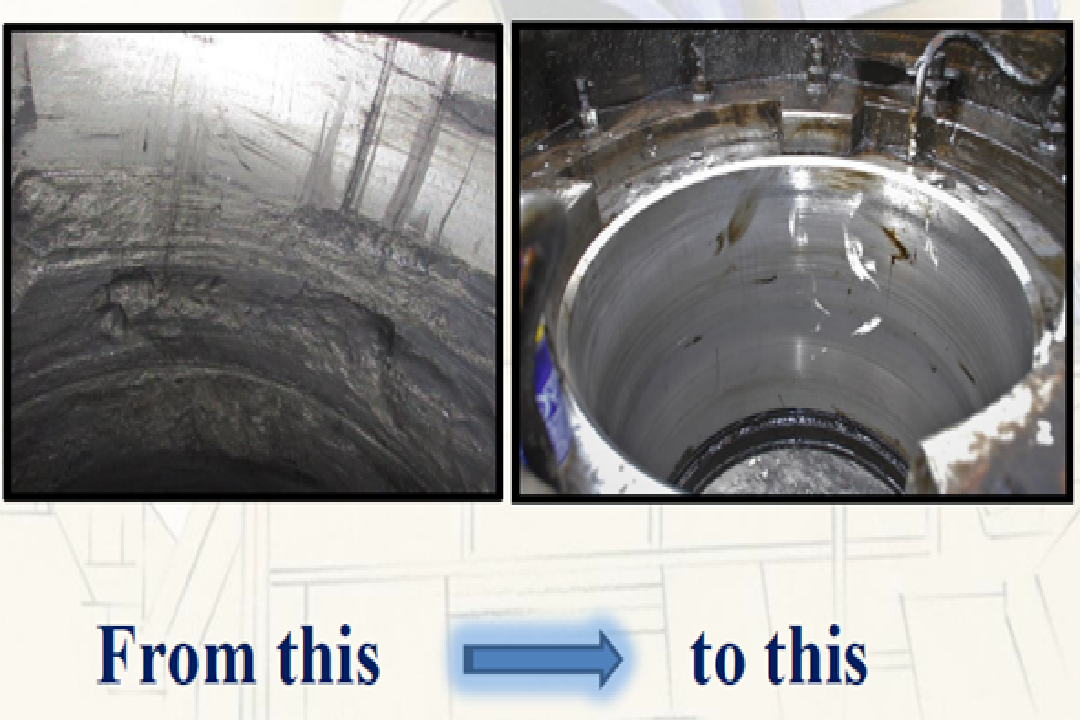

Lubricant – Proof Of Performance

Industry: | Mining | Equipment: | Gyratory Crusher |

|---|---|---|---|

Application: Nordberg 54-80 Gyratory Crusher Spider Bushing – Sleeve | |||

Description | Previous Condition | Current Condition |

|---|---|---|

Previous Product | Competitor Lithium Complex with 5% Moly NLGI 1 Grease. | The lubricant was changed to Petron Spider Bushing Lube in October 2018. |

Application Rate | Manually filled bushing reservoir to a depth of 1.5 inches for initial coverage. Connected to automatic lubrication system and set the ALS to pump for 15 seconds every 2,700 (45 minutes). | The application rate remained the same as that of the previous lubricant. |

Condition |

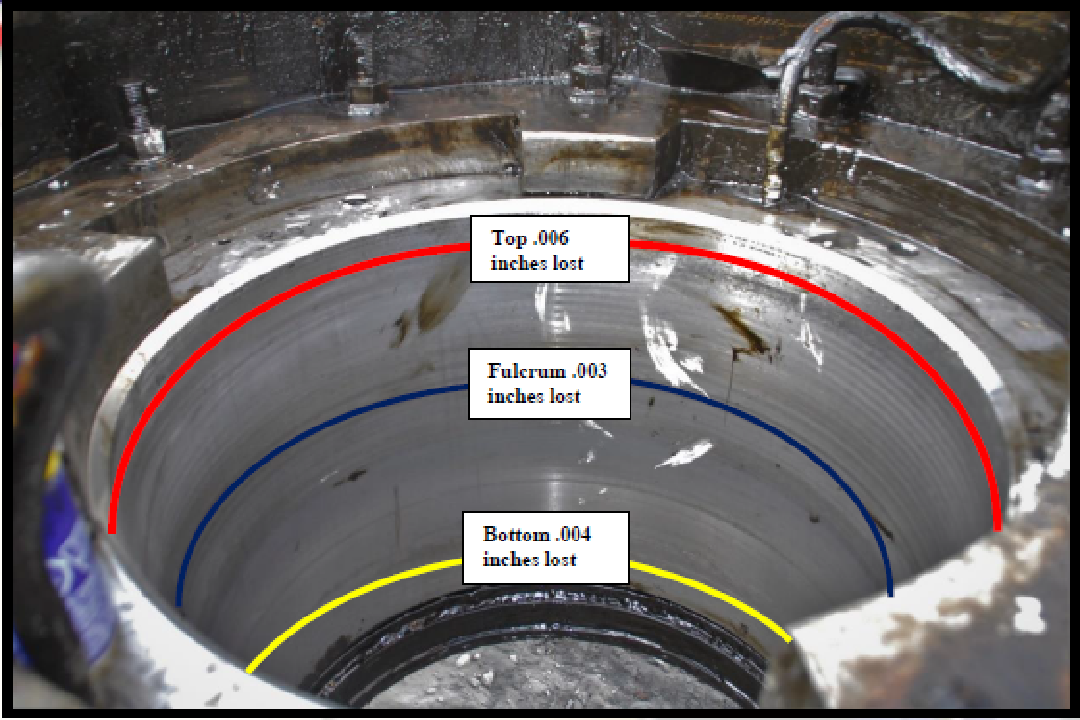

| After six months of operation as disassembled, and the Spider busing was measured, please refer picture and table below. Also refer below are the benefits of using Petron Spider Bushing Lube. |

Dimension | Coordinates | Original Bushing | Bushing Diameter | Difference |

|---|---|---|---|---|

Top | East – West | 24.138 | 24.144 | 0.006 |

North – South | 24.138 | 24.144 | 0.006 | |

Fulcrum | East – West | 24.14 | 24.143 | 0.003 |

North – South | 24.14 | 24.141 | 0.001 | |

Bottom | East – West | 24.138 | 24.142 | 0.004 |

North – South | 24.138 | 24.141 | 0.003 |

Benefits of using Petron Lubricant for Spider Bushing

Lesser wear due to heavy viscous base oil with naturally occurring tackifiers covering the entire surface of the Spider Bushing during operation. When the Spider Busing is properly lubricated there is less corresponding stress on the mantle shaft and the eccentric bearings that stabilize the mantle during operation.

-

No metal to metal to contact during shock loading.

-

Extended Spider Bushing life from 6 months to potentially 3+ years. Potential cost savings of $150,000 on just spider bushing.

-

Results correspond with other Crusher that have reached 30,000 to 40,000 hours on a Spider Bushing using the Petron Crusher Lubricant.

Please visit for proof of performance related to lubricant cost savings and reduced maintenance cost of spider bushing of gyratory crusher.

To find out more about the Petron high-performance Lubricant for the gyratory crusher shaft and sleeve, please visit.

Please send your inquiries to Performance Products Tech (FZE), PPT (FZE), and Sharjah (UAE). Email: contact@performanceproducts.tech