To Learn about types of lubrication systems in the Cement industry & Open Gear Lubricants

We look at different types of open gear lubrication systems and how best to lubricate the various forms of open gear arrangements. Commonly used gears for power transmission, open/semi-enclosed gear drives (girth gears or heavy-duty gear drives) are since the beginning of the Industrial Revolution.

Application of open gear Lubrication system includes, including open gear lube spray systems;

Atomization / Spray systems

Drip-feed or Gravity-feed systems

Oil bath system (idler immersion and splash)

Hand, brush, or pour on (for small gears)

In general, a lubricant for an open gear lubrication system or other types of applications should be fluid enough to flow through equipment elements/parts in case applied by a drip-feed system, force-feed lubricator or spray system. Similarly, in brush applications (for small gears) the open gear lubricant needs to be sufficiently fluid enough for an evenly spread coat to be brushed onto the teeth of gears

Open gear lubrication system: In any case, it’s important and necessary for the open gear lubricant to be tacky and viscous to resist the squeezing out from the gear meshing teeth. In case of a splash pan or a splash and idler immersion type lubrication system is used, the gear lubricant drips inwards so it is important for it not to be so thick and heavy that it channels as the gear teeth dip into it. Ideally lubricant for open gear lube spray should have the following properties, for lube spray on open gears for longer life of gears.

Learn About What Are The Prerequisite For Open Gear Lubrication System

Excellent adhesion to open gears Lubrication system and resistance to extrusion under extreme pressure.

Tackiness (adhesive/cohesive properties) of lubricant on gears.

Provide gears an elastic retractable film that cushions the loads and lubricates load bearing surfaces and minimizes metal-to-metal contacts.

Resistance to fling-off from the gears.

No build-up in the roots of the gear teeth.

Pumpability in all weather conditions.

Adequate film thickness – Lamda.

Resistant to water washout and spray-off.

Protection of the gears against rust and corrosion.

Spray ability and/or ease of dispensability.

Alleviate housekeeping and maintenance issues.

Environmentally friendly.

Giving considerations to the properties, applications and methods best suited for open gear lubrication there are a variety of products are available in market to choose from. Lubrication products work on various principals of lubrication but the most effective being electrohydrodynamic (EHD) type lubrication for open gear lube spray. Some of lubrication products for open gear lube spray use boundary lubrication with the help of solid lubricants such as graphite, desulphated and molybdenum, as part of their makeup to separate metal to metal contacts.

The Petron Gear Shield meet the properties and performance criteria required to properly and successfully lubricate the open gears lube spray for open gears in Cement, Mining or other industries for spay type systems / applications.

Types of Lubrication System & Open Gear Lubrication.

The open gear lubrication types are as follows:

Semi-fluid greases (also known as paste type)

Asphaltic type (also referred to as residual compounds)

Gel/polymer-thickened types

Semi-fluid grease cutbacks

High viscosity synthetics

The Petron Gear Shield meets the properties and performance criteria required to properly and successfully lubricate the open gears lube spray for open gears in Cement, Mining, or other industries for spay-type systems/applications. Please find below the open gear lubricants types, for using lubricants spray and sump & splash applications;

HOW TO SAVE YOUR GEARS – REDUCE THE LUBRICANTS AND MAINTENANCE COSTS:

PETRON OFFERS GEAR SHIELD – ONE OF BEST LUBRICANTS FOR OPEN GEARS LUBE OIL SPRAY:

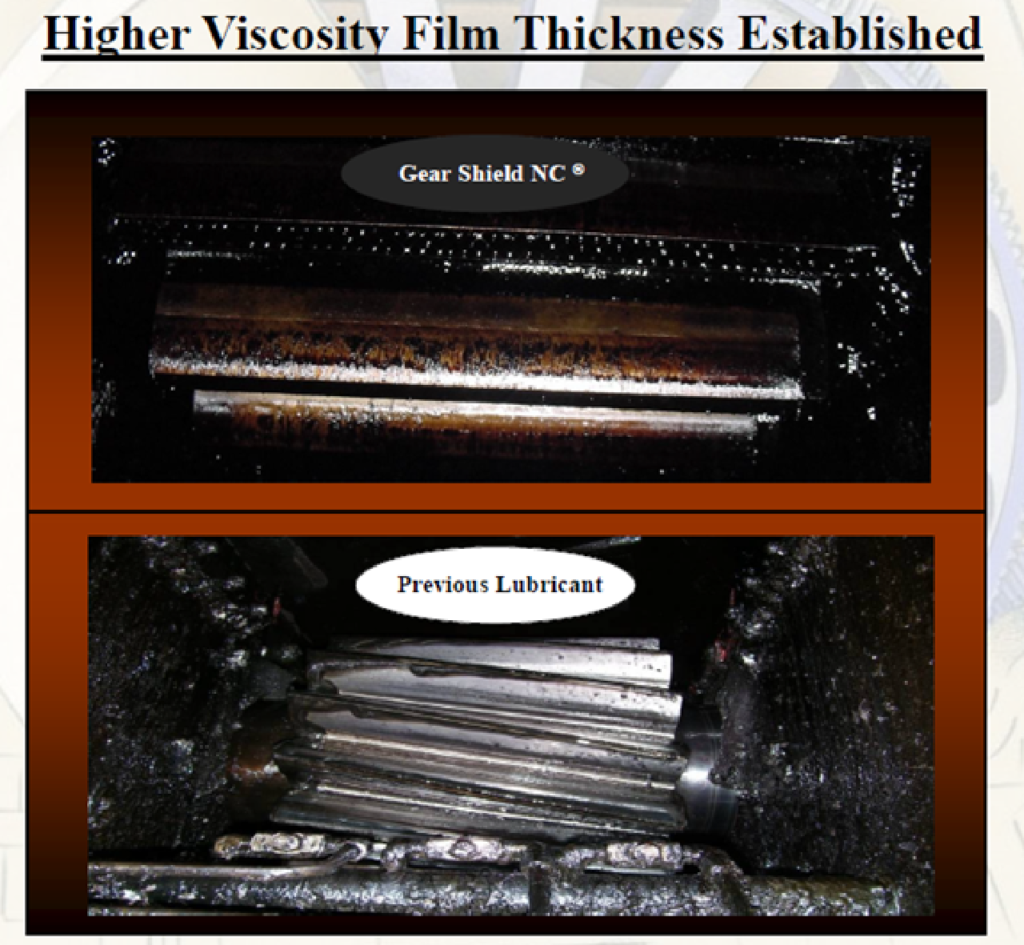

Higher lube thickness (Lambda) – lesser wear of mating surfaces.

Higher Viscosity Fluid designed to lubricate heavily loaded open gears.

Industry-leading FZG wear test result (0.0532 mg/kWh). Reduced wear thus longer life and lesser maintenance.

Anti-wear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones of gear tooth mesh.

No build-up in gear tooth roots.

Drains freely from gear guards.

Pumps freely down to 32°F (0°C). For applications below 32°F (0°C) use Gear Shield NCW.

Environmentally friendly. Does not contain chlorinated solvents or lead and is free of all carcinogens.

Environmentally Safe/Passes TCLP Protocol A

Translucent—Easy visual inspection of gears during running condition.

Excellent Lube Film –Owing To The High Lamda Values Which In Turn Results Better Separation Of Gear Tooth, And Stop Progression Of Pitting.

Please visit the page to learn more about elimination of lubricant build-up on gears tooth, consistent drainage, improved house keeping and other benefits of using Petron Lube for Kiln & Ball Mills Open Girth Gears.

The Petron Gear Shield® NC in Cement Industry allows 70% reduction in rate of application & cost. It provides consistent drainage which eliminates lubricant build up inside of gear guard and flushes airborne contaminants from gear. The benefits of using Gear Shield® NC are reduced cost for lubricant which results in lower reduced cost for waste disposal. It also reduces stress on pump which therefore reduces stress on lube lines.

“Petron passion is in manufacturing engineered lubricants for open girth gear applications, Petron expertise is in engineered lubricants. Lubricant types; Residual, Semi-Synthetic, Full Synthetic. ”

Excellence and Experience in Open Gear Lubrication System

Petron work on the forefront of innovation and engineered lubricants technology to take products from an idea all the way to the end consumer by meeting their special lubricant needs. We help hardware startups integrate technology, scale and desirability. We Help end consumers by integrating their needs with latest lubricant technologies.

Pumps freely down to 32 def. F (0 deg. C). For colder applications, i.e. ambient temperature below 0 deg. C use Gear Shield® NCW, below.

Pumps freely down to 0 def. F (-18 deg. C). For applications ambient temperature above 32® deg. C use Gear Shield® NC, above.

Pumps freely down to 0 deg. F ( -18 deg. C). For colder applications, heating may be required.

Why Choose Us?

Growth

We target growth margins to maximize your company’s profitability metrics.

Knowledgeable

With the best minds in the industry, we guarantee you’ll get a superb result with our product.

Experienced

Petron over 45 years of experience in open girth gear lubricants.

Targeted

With our expert staff we analyze and prepare a custom report with specific targets.